EVALUASI PENURUNAN VIBRASI MOTOR BUCKET ELEVATOR 51BE125-M2 PASCA PENGUATAN STRUKTUR

Keywords:

Machine vibration, Bucket elevator, Structure reinforcement, Predictive maintenanceAbstract

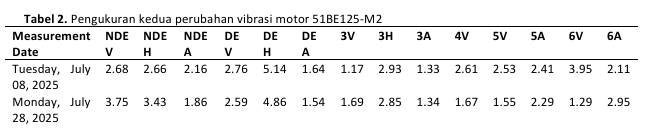

The cement industry requires high operational reliability, particularly in the kiln area where clinker formation occurs. One of the critical components supporting this process is the bucket elevator drive motor. The 51BE125-M2 motor at Baturaja II Plant operates under heavy load and high-temperature conditions, making it susceptible to increased vibration that may trigger mechanical failures such as misalignment, unbalance, structural looseness, and bearing damage. Initial measurements indicated that the motor’s vibration level was within the hazardous category based on ISO 10816, accompanied by harmonic components in the FFT spectrum that signaled structural looseness in the foundation and motor mount. This study analyzes the effect of structure reinforcement on reducing motor vibration by comparing conditions before and after corrective actions. A quantitative experimental method was employed, with vibration measurements taken using VIBXpert II in three directions (horizontal, vertical, and axial). Corrective actions included retightening foundation bolts, installing reinforcement plates, repairing mounting gaps, welding weakened points, and realigning the motor base. Post-repair measurements showed a significant reduction in RMS vibration values and the disappearance of 2×–4×RPM harmonics. According to ISO 10816 classification, the motor’s condition shifted from a hazardous zone to a safe zone. The findings confirm that structural reinforcement is effective in reducing vibration and enhancing the operational reliability of the bucket elevator.