ANALISIS KEGAGALAN SHAFT PADA GEARBOX FLENDER B2SH10D

Keywords:

Shaft failure, Flender B2SH10D gearbox, Fatigue fracture, High torqueAbstract

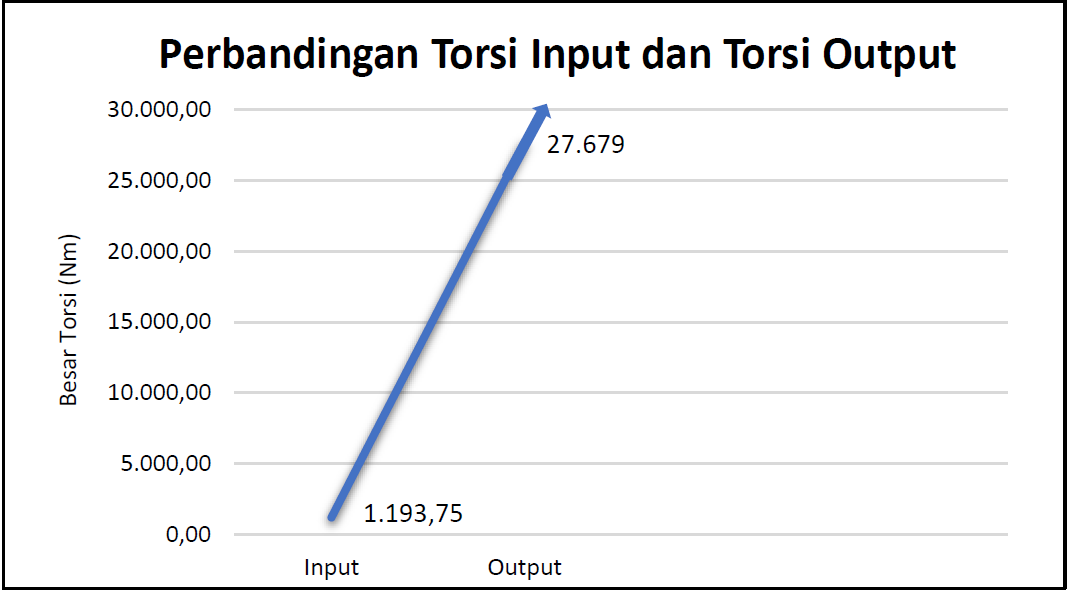

This study aims to analyze shaft failure in the Flender B2SH10D gearbox used in the coal distribution system. Failure of this shaft is a significant problem that disrupts the coal loading process. The results of the analysis show that the main cause of shaft failure is the high torsional load received by the output shaft, reaching 27,679 Nm, which causes high stress concentration on the keyway. This is exacerbated by misalignment between the motor and gearbox and humid environmental conditions, which accelerate the corrosion process on the shaft. The failure that occurred was a fatigue fracture, which began with microcracks in the stress concentration area and then developed into a total fracture due to repeated cyclic loads. The recommendations given include the use of shaft materials with higher fatigue resistance, the implementation of better preventive maintenance, and the use of optimal lubrication methods to prevent similar incidents in the future. This research is expected to serve as a reference for improving the performance and reliability of gearboxes in the future.